Syntron Materials Handling

Belt Conveyor Idlers

For over 100 years, Syntron Material Handling (SMH) and the Link-Belt ® Company have designed and manufactured belt conveyor parts including conveyor idlers (rollers) and components that set the standard of excellence for bulk material handling throughout the world.

Bucket Elevators

Link-Belt® Bucket Elevators, manufactured by Syntron Material Handling, have long been the industry standard for any bulk material elevating application.

Heavy Duty Feeders

Syntron® Vibrating Feeders for heavy industry are ideal for feeding a wide variety of bulk materials from storage piles, hoppers, bins and silos. Rugged and dependable, Syntron® heavy-duty feeders are backed by years of service-proven performance in the mining, aggregates, glass, cement, chemical, wood products and steel industries.

Paper Joggers

Syntron® Paper Joggers provide high performance jogging solutions for a broad range of applications with unparalleled efficiency and reliability. Syntron® Paper Joggers are found throughout the world in newspaper operations, banks, printing shops, post offices, catalog operations, mailrooms, offices, binderies, label manufacturing operations, department stores and computer operations.

Light Industry Feeders

Syntron® Vibrating Feeders for light industry offer unmatched flexibility and reliability, making them ideally suited for a number of applications and materials. They are typically used in feeding, mixing, blending, batching, grinding, packaging, flaking, freezing and drying applications. Whether the material is hot or cold, fine or coarse, dry or damp, light or heavy, these versatile units handle it with ease and efficiency.

Screening Feeders and Screens

From coal to food processing, to plastics, pharmaceuticals and other processes, Syntron® Screen Feeders are employed to scalp, separate, size, de-dust and de-water bulk products. Powered by highly efficient electromagnetic drives which provide gentle handling with minimal product degradation, Syntron® Screen Feeders have no moving parts, which means no lubrication is required and ongoing maintenance is minimal. Units range in size from a tiny, three-inch-wide pill de-duster to the massive four-foot-wide models used in heavy industry. Syntron Material Handling also offers electromechanical designs for high-tonnage screening of coarse materials.

Screw Conveyors

Syntron Material Handling and its predecessor, Link-Belt ®, pioneered the early development of industrial screw conveyors, screw feeders and related conveyor components. For more than 125 years we have designed and manufactured high-quality screw conveyors and components that set the standard of excellence in the bulk material handling industry. Vast design engineering and production experience sets Link-Belt ® Screw Conveyors apart from our competitors in quality, reliability and dependability.

Vibrating & Materials Flow Aids

Syntron® vibrators offer an efficient, cost-effective means to maintain free flow of product from bins, hoppers and chutes, with a direct and positive result on the bottom line. Whether the need is to ensure constant, uninterrupted material flow, or to eliminate the necessity for manual manipulation of a bin, hopper or bulk material, Syntron® Vibrators increase productivity and reduce production costs.

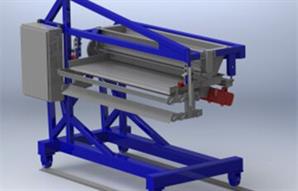

Vibrating Conveyors

Transfer a wide variety of bulk materials along a trough with a uniform and consistent flow.

Flexmount Oscillating Conveyors Light to medium-duty applications

- Flat Springs

- Used in chemical, forest products and metal processing industries

Coilmount Oscillating Conveyors Large capacities of low to high density materials

- Coiled Springs

- Free-Flowing, Sticky or Fragile Material Applicaitons

- Modified for Screening, Scalping, Spreading and Dewatering Applications